Our ASTM 790 Super Duplex Steel Welded Pipes are multi-purpose and possess good weldability, used widely in the offshore and marine industry for their acid corrosion resistance. ASTM A790 Super Duplex Steel UNS S32750 Pipes are highly alloyed with different metals and have greater mechanical strength. These pipes have a high chloride corrosion resistance, suitable for chloride-aggressive operations.

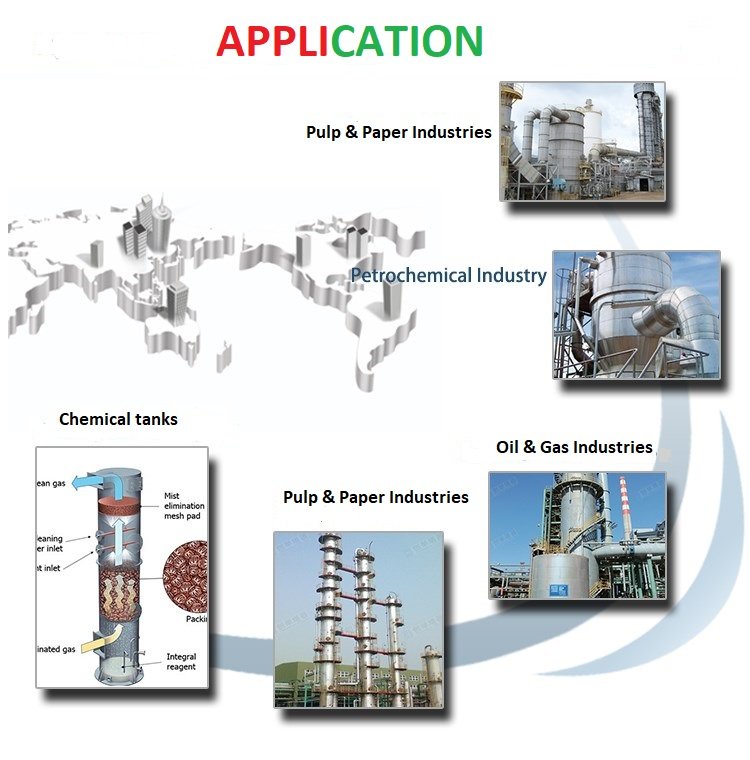

We manufacture, export & supply UNS S32750 Super Duplex Steel Tubes to spheres of industries ranging from basic industries such as Sugar, Paper, Textile, and Engineering to more complex such as Oil & Gas, Petrochemical, Chemical & Fertilizers, Power Generation and Nuclear Industries. Super Duplex Stainless steels, which combine high strength and excellent corrosion resistance in many environments, have found applications in chemical and process industries. Pulp mills, offshore systems, flue gas desulphurization units. The localized corrosion resistance of Super-Duplex Steels is close to what is achieved with 6% Mo Super-Austenitic grades. Our company pays close attention when packing UNS S32750 pipes and tubes to guarantee the best possible condition upon delivery to our customers. We source top-quality packaging materials that are strong, long-lasting, and can endure hurting in transit. Each pipe and tube is counselled and shrouded in a protective covering to prevent scratches or other damage. Durable wooden crates and pallets are then used to provide secure packaging for the pipes and tubes. Our team is particularly cautious about packing the pipes and tubes to ensure they remain stable and that no shifting occurs during transportation, which lessens the likelihood of damage.