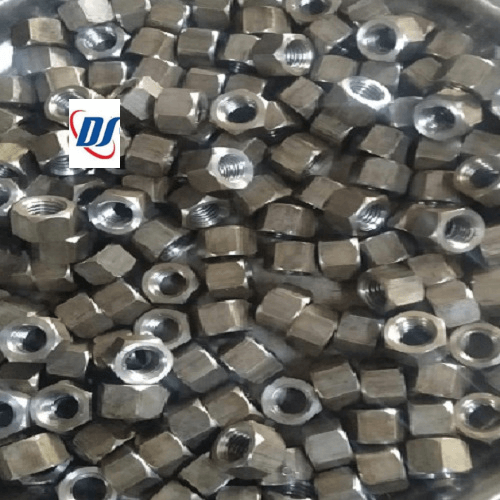

Best quality raw materials are used in order to manufacture these Duplex S32205 Fasteners. The chemical composition of these Duplex Steel S32205 Fasteners comprises chromium and molybdenum along with nickel. This makes the chemical composition excellent. Therefore, these Duplex S32205 Fasteners are of both nature, that is, ferritic and austenitic. These Duplex S32205 Fasteners have the property of workability, and therefore they perform well.

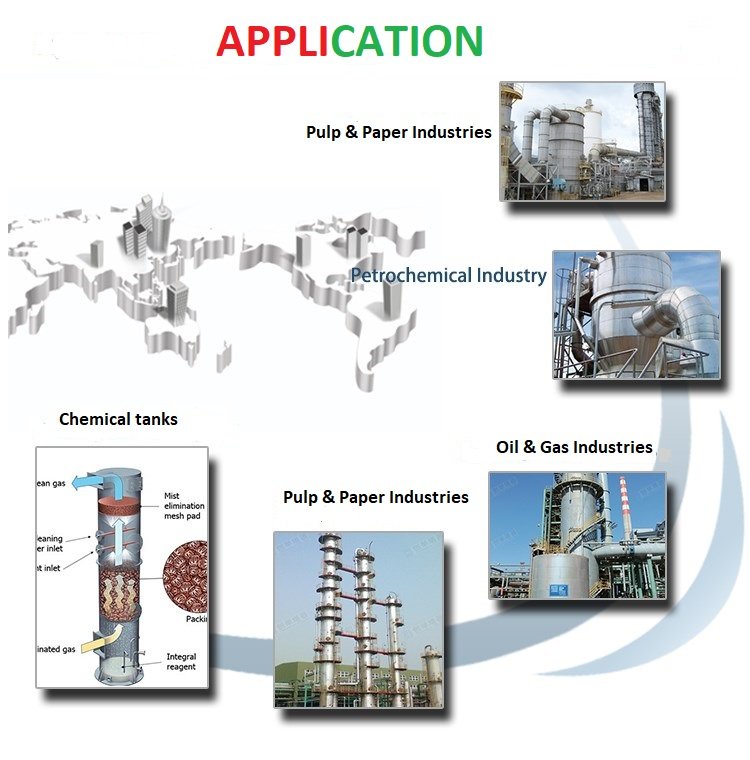

High-temperature bound environments are where these Duplex S32205 Fasteners could be utilised. These Duplex S32205 Fasteners could also be used with environments that are bound with high pressure. The Duplex S32205 Fasteners also has excellent finishing. Another property that these Duplex S32205 Fasteners have is flexibility. Along with being ductile, these Duplex S32205 Fasteners also have a longer functional life. These are also dimensionally accurate.

The necessary industrial standards, as well as guidelines, are kept in mind while producing these Duplex S32205 Fasteners so that they fulfil the demands of the clients. The Duplex S32205 Fasteners also go through various testing processes so that the UNS S32205 Duplex Fasteners that are produced are of excellent quality and that they perform well. The Duplex S32205 Fasteners could be made according to the specifications that are given by the client or also according to the needs of the application.