DUPLEX STEEL & ENGINEERING is Well-known for manufacturing, supplying and exportinga widespread collection of world-class, high quality Stainless Steel 17-4H Round Bars, which is high-combination austenitic stainless steel with low carbon content. Our large assortment of Stainless Steel 17-4H Bars is known for good corrosion, heat, oxidation resistance, and its decorative nature. The evaluation is expected for use of Stainless Steel 17-4H Round Bars under extreme destructive conditions. Our Staibnless Steel 904L Hollow Bars is completely austenitic and is less delicate to precipitation ferrite and sigma stages than customary austenitic evaluations with high molybdenum content.

Our offered Grade 904L Stainless Steel Hexagonal Bars have a number of excellent features like resistance against corrosion, precise dimensions, wear resistance, stability, and so on. These 904L also reffered as UNS N08904, Our product SS 904L Threaded Bars has raised quality, top notch hardness and wear resistance, alongside direct erosion resistance.

Type 17-4 PH Stainless steel is the most widely used of all of the precipitation- hardening stainless steels. Its valuable combination of properties gives designers opportunities to add reliability to their products while simplifying fabrication and offen reducing costs. Type 17-4 PH is a martensitic precipitation-hardening stainless steel that provides an outstanding combination of high strength, good corrosion resistance, and good mechanical properties at temperatures up to 600o F (316oC). Its unique combination of properties make this alloy an effective solution to many design and production problems.

Resistance to Corrosion :

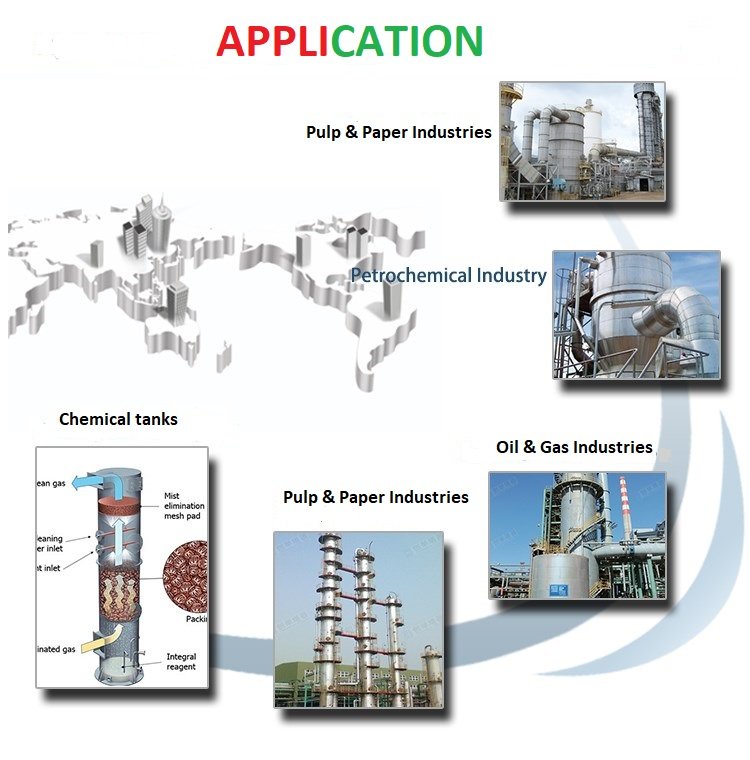

Type 17-4 PH stainless steel has excellent resistance. It withstand corrosive attack better than any of the standard hardenable stainless steels and is comparable to type 304 in most media. this has been tested in a wide variety of corrosive conditions in the petrochemical, petroleum, paper, dairy and food processing industries, and in applications such as boat shafting.

GENERAL CHARACTERISTICS :

- Excellent resistance to corrosion

- Provide toughness in both base metals and welds.

- Well suited to applications that require ease of fabrication and then the addition of strength / hardness for improved reliability