DUPLEX STEEL & ENGINEERING is a leading organization invoved in manufacturing, exporting of superior range of Super Duplex Steel S32750 Flanges, which made from Best Quality of Standard Raw Materials and are outlined according to with national and global norms. UNS S32750 ASTM A182 Flanges convey the good resistance to chloride pitting and crevice corrosion due to the combination of chromium, molybdenum and nitrogen. We aprovide Super quality Super Duplex S32750 Oriface Flanges, the application of an orifice flange is to offer admittance to a line for metering of liquids or gases.

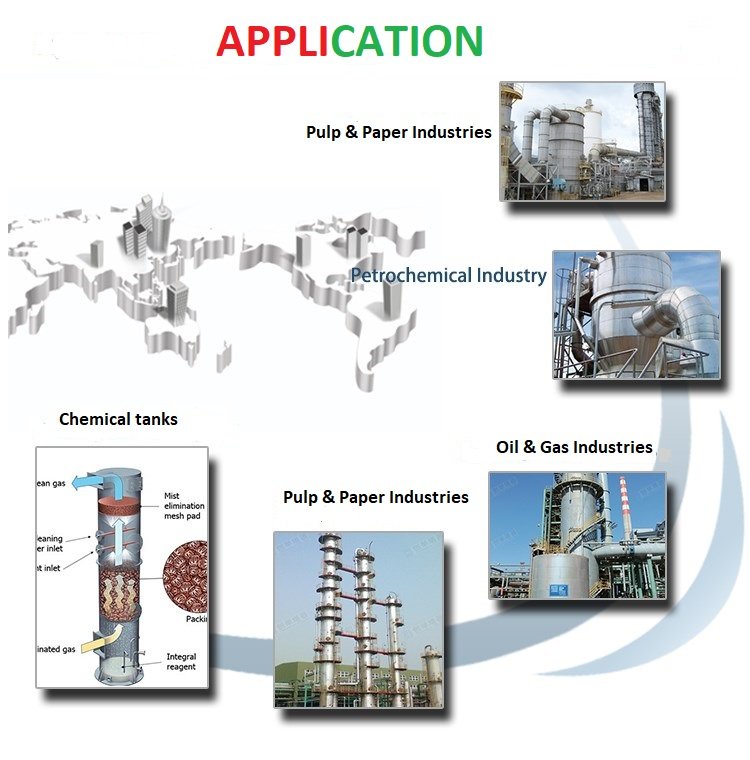

This exotic alloy Super Duplex F53 Spacer Ring Flanges is used in oil and gas exploration, chemical processing industries also make use of this alloy. Mechanical assemblies and infrastructure relies on Super Duplex 2507 Slip on Flanges for their ability to withstand a high mechanical load in seawater. Super Duplex Stainless steels, which combine high strength and excellent corrosion resistance in many environments, have found applications in chemical and process industries. Pulp mills, offshore systems, flue gas desulphurization units. Localized corrosion resistance of Super-Duplex Steels is close to what is achieved with 6% Mo Super-Austenitic grades.

The 2507 is the most widely used of the Duplex stainless steels occupying more than 80% of the duplex stainless steel market. The 2507 alloy provides better corrosion resistance in various environments where 316L is generally used with an added advantage of its higher yield strength. All 2507 alloys are metallographically examined to ensure that the shipped product is free from presence of detrimental phases such as sigma. It is often used in form of welded pipe or tubular components. The alloy has also been applied as a formed and welded sheet product in environments where resistance to general corrosion and chloride stress corrosion cracking is important.