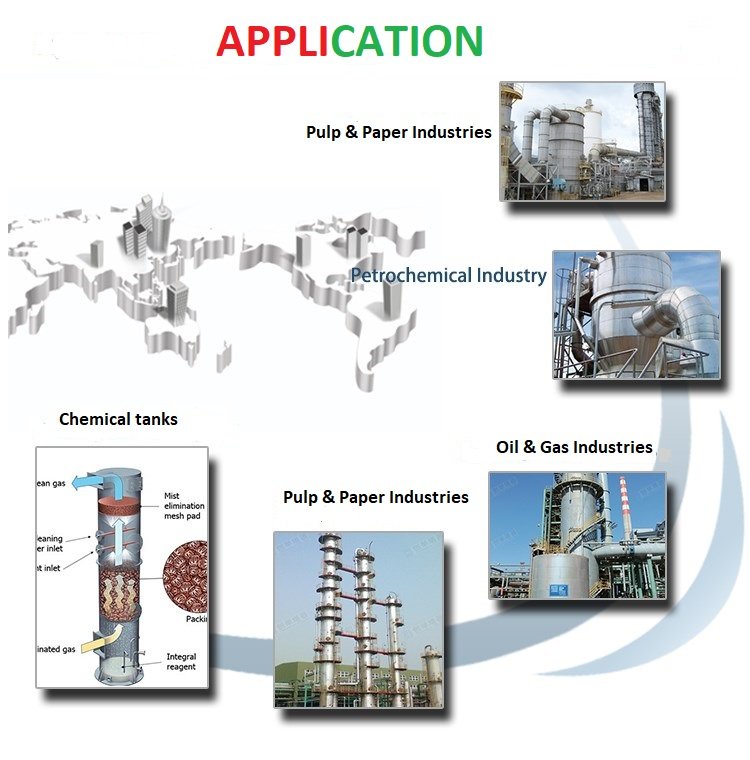

DUPLEX STEEL & ENGINEERING well known manufacturer, exporter and supplier of Stainless Steel 17-4H Flanges, These UNS N08904 Flanges are available in different range of diameters, wall thicknesses and sizes at market leading prices. Grade 904L Flanges contains high amounts of expensive ingredients, such as molybdenum and nickel. The austenitic structure also gives WerkdtoffNr. 1.4542 SS 904L Slip On Flanges excellent toughness, even down to cryogenic temperatures. We are making SS 904L Weld Neck Flanges that are particularly created in a way that the separation crosswise over of the channel perfectly fits the width of the Stainless Steel 17-4H Flanges.

We used high ss grade while making of SS 904L Spectacle Blind Flanges, which is one of the few stainless steels that at temperatures of up to 35 Degree C/ 95 Degree F provides full resistance in dilute sulfuric acid environments within the entire range of concentration. Type 17-4 PH Stainless steel is the most widely used of all of the precipitation- hardening stainless steels. Its valuable combination of properties gives designers opportunities to add reliability to their products while simplifying fabrication and offen reducing costs. Type 17-4 PH is a martensitic precipitation-hardening stainless steel that provides an outstanding combination of high strength, good corrosion resistance, and good mechanical properties at temperatures up to 600o F (316oC). Its unique combination of properties make this alloy an effective solution to many design and production problems.