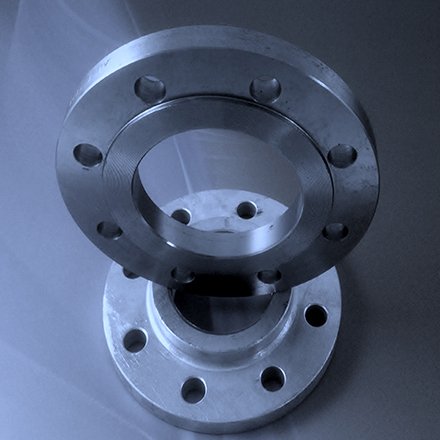

DUPLEX STEEL & ENGINEERING is acknowledge as one of the large manufacturer, exporter and supplier of Stainless Steel 410 Flanges, this are also known as UNS S41000 Flanges, universally useful martensitic stainless steel that is utilized for exceptionally focused on parts and gives great erosion resistance in addition to high quality and hardness.

Alloy 410 is the basic, general purpose martensitic stainless steel that is used for highly stressed parts and provides good corrosion resistance plus high strength and hardness. Compound 410 Socket weld Flanges contains at least 11.5% chromium which is sufficiently adequate to show consumption resistance properties in gentle climates, steam, and numerous mellow synthetic situations. We are stock & supply Stainless Steel 410 Slip On Flanges is tough and chips build up on tools in softest condition.