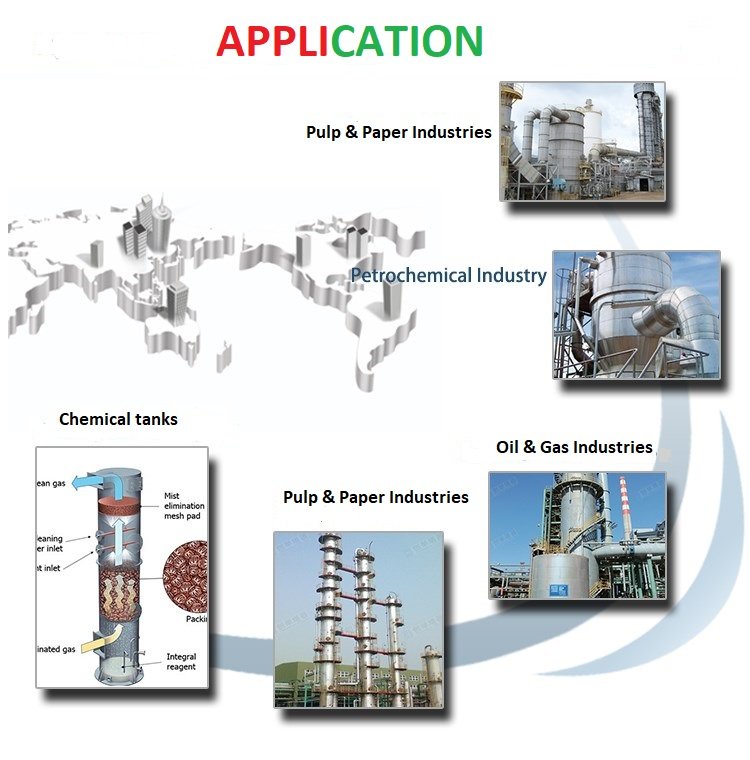

DUPLEX STEEL & ENGINEERING is one of the most manufacturers and suppliers of Stainless Steel 304 Buttweld Fittings. Our ASTM A403 Stainless Stel Elbow Fittings have resistance to atmospheric corrosion and are economically viable and for small scale applications such as sealing tube ends. These UNS S30400 Long Radius Elbow usually use in the paper, fabric, and printing industry because of their excellent soldering properties. The SS Reducer Fittings provided have a high carbon content, reducing the fusion point, and increasing the resistance to heat.

In a wide range of chemicals, particularly the acidic chloride environment, such as the ones in pulp and paper mills, the SS 304H Pipe Fittings has an excellent corrosion strength. In this Stainless Steel 304L Elbow, higher levels of Chromium, Molybdenum, and Nickel improve chloride pitting resistance and general corrosion. Dish Cap tube fits are resistant to sulfuric acid at 120 degrees F (49 degrees C) at temperatures of 5% higher than 304 degrees C, and the molybdenum alloy content increases. In welding conditions, even in severe corrosive conditions, Tee Pipe Fittings can be used with Stainless Steel 316 Buttweld Fittings. Stainless Steel 304 End Cap often eliminates the need for ringing welds except for stress relief applications. We specialize in delivering the right fits into the natural gas and chemical industries of class SS 304L Equal Tee. We also supply SS 304H Butt Welded fitting, which has been built using the comprehensive center joint system, in which welded but used fillings are cut to the right angle and welded in tandem for required changes.