DUPLEX STEEL & ENGINEERING is one of the famous Stainless Steel 316 Buttweld Fittings suppliers and distributors, and it is an offer to our customers in various sizes and shapes. Our Stainless Steel 316L Long Radius Elbow also meets another important criterion of sustainable material, apart from having an excellent track record of recyclability and end of life recovery rates. When selected to attend the corrosion conditions of the environmental environment, the SS UNS S31600 Pipe Fittings can usually fulfill the project's lifetime requirements.

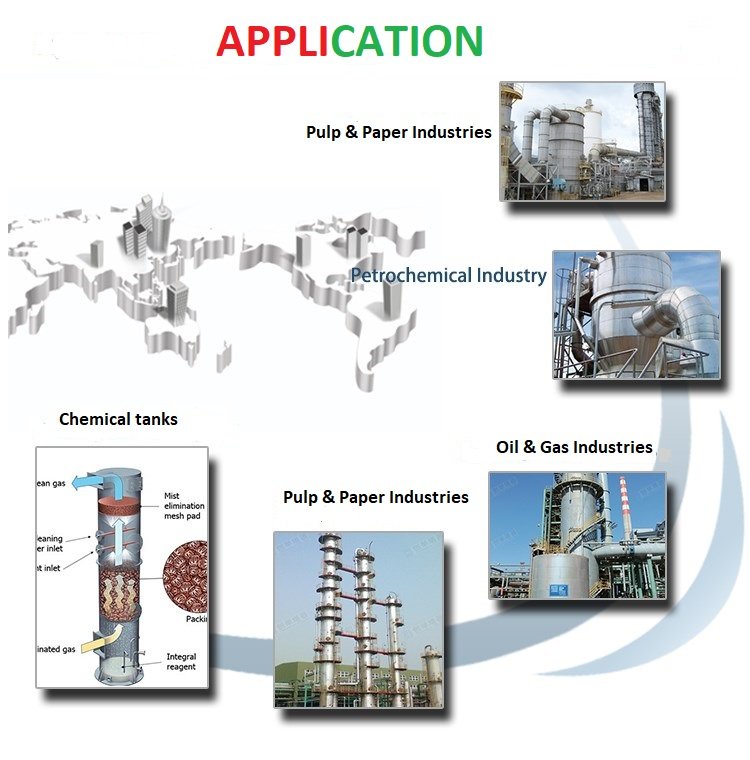

In intermittent service at 870 ° C and continuous service at 925 ° C, Stainless Steel 316L End Cap is good for oxidation resistant. Ongoing use in 425 ° C–860 ° C is not recommended in the SS 316Ti Reducer Fittings if resistance to corrosion is necessary for water. Unable to heat treatment to harden the Stainless Steel 304 Buttweld Pipe Fittings. Cleaning in 316Ti Bends Butt Weld Pipe Fittings in Stainless Steel can be achieved after heating to 1010 Degree C–1120 Degree C. In this situation, the SS 316Ti Stub End is preferred as a result of its carbide precipitation resistance. SS 316L Pipe Fittings can be rinsed and used in power plants, pressurized vessels, boilers and condensers with a higher carbon version, which is qualifying for use at higher temperatures. In oxidizing and reducing environments, they not only reduce the corroding in moderate temperatures, but they are also resistant. The large-scale industries using 316 SS Seamless Tubes are the maritime, petroleum, chemical, petrochemical, and industrial processing industries and the chloride industries.