316 Stainless Steel Pipe is a generic class of stainless steel austenitic molybdenum-bearing. It is austenitic, non-magnetic, and non-hardenable in terms of heat. Molybdenum alloying component provides more corrosion resistance to type 316 than steel and iron or even 304 stainless steel Pipe. Under chemical, salt, and acidic conditions, it is exceptionally resistant to pitting and crevice corrosion.

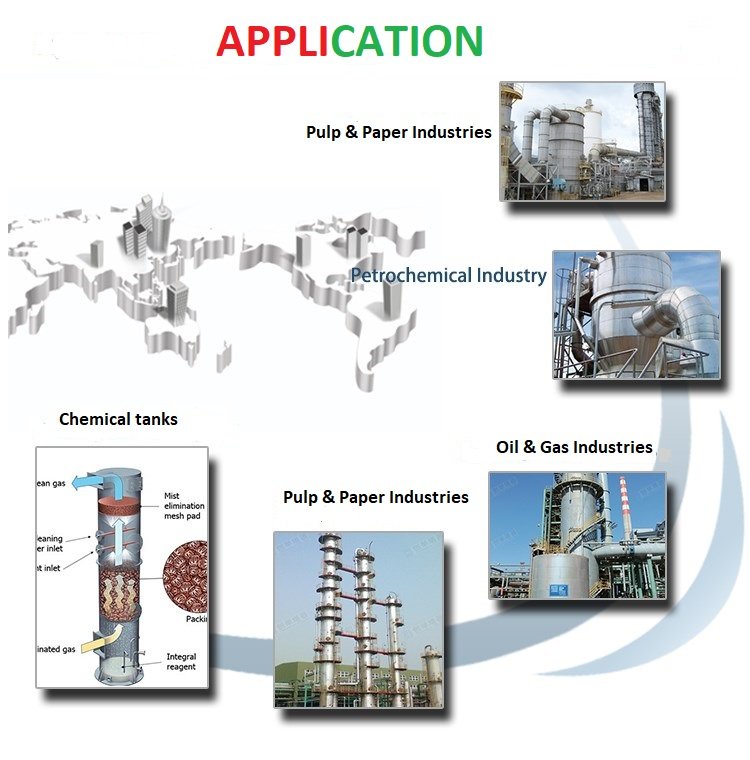

The addition of molybdenum to our Stainless Steel 316 Seamless Pipes offers improved resistance to corrosion in chloride environments in general. The excellent design and welding characteristics of SS 316 tubes widely used for marine, petrochemical, electric, and inner-architectural uses. Generally, UNS S31600 stainless steel 316 pipe is a better choice for forming operations as the higher molybdenum content in grade SS 316 Pipe means that it has higher strength and work-hardening levels that can adversely affect formability. While Stainless Steel 316 can usually be drawn and shaped in a similar fashion to 304, variations in temperature will challenge those processes. For example, when cold worked the 316 alloy can become magnetic. 316L stainless steel pipe is commonly used in oil and gas, LNG, Thermal, Nuclear, Chemical, Fertilizer, Petro, Shipbuilding, Desalination, Water, Energy, EPC, and General Engineering pipes industries. Such TP 316 Stainless Steel Pipe is available in various lengths, shapes, and models at a reasonable price as per customer requirements.

Key CHARACTERISTIC :-

- Corrosion resistance

- Resistance to oxidation and sulfidation

- Surface finish

- Magnetic properties

- Ductility

- Suitability for intended fabrication techniques