Our manufactured 317 Stainless Steel Pipes are used by our clients in industries with more than average corrosion resistance requirement. The increased carbon content in Stainless Steel 317L Tube delivers a greater tensile and yield strength. These Stainless Steel 317 EFW Pipes is a higher molybdenum austenitic stainless steel further alloyed with nitrogen to provide improved corrosion resistance relative to SS 316L and SS 317L, especially in acidic chloride - containing environments.

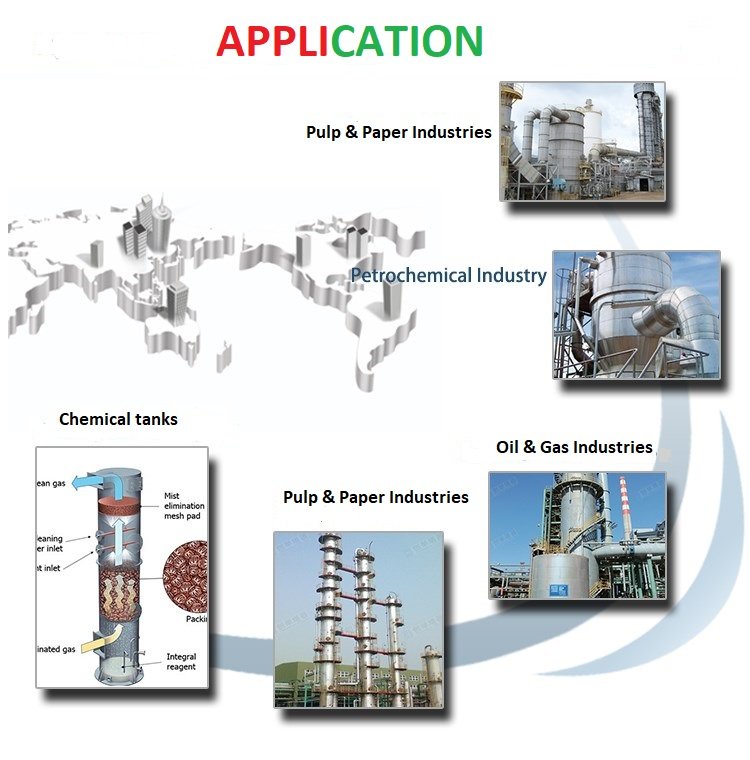

The high strength and corrosion resistance of 317L Stainless Steel Pipes are the same as 317 steel, but their low carbon content will produce stronger welds. AISI 317L pipes require low speeds and constant feeds to reduce their tendency to harden. Alloy 317L Pipes are widely used for the processing and production of chemicals and petrochemicals, pulp and paper, and fossil-fuelled, nuclear condensers. Our Type 317 Stainless Steel UNS S31700 Seamless Pipes are made of 100% stainless steel for use in marine and automotive applications and deliver specific stresses. In applications where the attachment must be adjustable, SUS 317L Pipes can also use. With hundreds of different types of steel alloys on the market, our Stainless Steel 317/317L Pipes can be tough to find the perfect metal for your application. These SS 317, UNS S31700 pipes are available in different form Round, Square, Rectangle, Oval, Coil, Flexible Pipe, Shaft, 'U' Shape, Hydraulic Tube etc.

Key CHARACTERISTIC :-

- Corrosion resistance

- Resistance to oxidation and sulfidation

- Surface finish

- Magnetic properties

- Ductility

- Suitability for intended fabrication techniques